- Home

- Department

- Features

- Adjustable (3)

- Array (19)

- Automatic (33)

- Automatic Cleaning (24)

- Automatic Watering (4)

- Cool Touch (3)

- Display (4)

- Durable (5)

- Easy Clean (12)

- Electric (9)

- Heated (13)

- Manual (6)

- Non-stick (43)

- Portable (42)

- Portable, Efficient (3)

- Rapid Ice Making (3)

- Stable Performance (3)

- Stainless Steel (3)

- Viewing Window (3)

- Water Dispenser (4)

- Other (2733)

- Material

- #304 Stainless Steel (10)

- 304 Stainless Steel (14)

- Abs (5)

- Abs Plastic (10)

- Aluminum (10)

- As Description (20)

- As Description Shown (5)

- Carbon Steel (4)

- Food Grade Material (4)

- Iron (8)

- Metal (43)

- Pc; Stainless Steel (14)

- Plastic (61)

- Stainless Steel (412)

- Stainless Steel+ Pc (3)

- Stainless Steel+ Pvc (4)

- Stainless Steel+abs (6)

- Stainless Steel. Pe (7)

- Steel (14)

- Steel Grey (16)

- Other (2302)

- Model

- 001 (12)

- As Description (19)

- Bi-zjgj-2188 (22)

- Bosch Hmt72m450 (11)

- Bykccp173ahuk-ukas3 (36)

- Dc-100k (46)

- Donut Maker Machine (10)

- Fy-1102b (16)

- Fy-1104b (12)

- Ice Cube Maker (27)

- Lb55s (11)

- Mini Donut Maker (118)

- Nt-icemaker-bk (16)

- Nx-60 (18)

- Slush Machine (19)

- T-101 (18)

- Tkx-03 110v (34)

- Tkx-04 110v (20)

- Xrj15x3 (24)

- 225 (11)

- Other (2472)

- Power Source

- Size

- 1.46''(37mm) (2)

- 11cm(4.33inch) (2)

- 145x249mm (2)

- 15.5 X 23.5 X 12cm (4)

- 2-1 / 4\ (4)

- 23cmx8cmx37cm (2)

- 260*210*190mm (2)

- 26lbs / Day (3)

- 34 *27*23cm (22)

- 37mm (2)

- 58x21x16cm (28)

- As Description (18)

- As Description Shown (5)

- Black (7)

- Customized (3)

- Icm-1232 (2)

- Regular (3)

- Stainless Steel (10)

- Up To 2.2lb Loaf (2)

- Other (2849)

New 220v Automatic Dumpling skin wrapper making machine Dumpling wrapping maker

Wrapper Dumpling maker Dumpling wrapping machine. Please copy the following URL to watch the video of this product.

The machine is made of 304 stainless steel and ordinary steel. Its structure is reasonable, maintenance, disassembly and cleaning are simple and convenient, and it has high efficiency and energy saving.

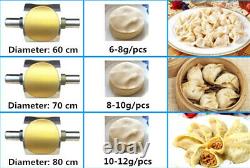

Safe use, no corner waste, one-time shaping, medium thickness and thin edges, etc. Make dumpling wrapper uniform in appearance, taste and weight, thus completely changing the current situation of low production efficiency, waste of employees, secondary pollution, imperfect shaping of middle dumpling wrapper and easy cracking.In addition to the above advantages, the machine can also customize the size and thickness of dumpling wrapper according to customer needs. The emergence of the machine has attracted the attention of the dumpling industry dumpling production line can be formed by choosing matching equipment such as dough machine, surface pressing machine, conveyor belt, etc. Brake dumpling leather mill roll arrangement, chain sprocket transmission, easy maintenance.

Automatic dumpling leather feeding machine, automatic shaping, thick edge book, no corner waste. The roll of the automatic dumpling leather mill has the advantages of uniform feeding, neat panel and labor saving. Advantages of Dumpling Leather Machine. The conveying surface and forming parts of dumpling leather machine are made of special adhesive materials.

Dumpling leather machine has scientific structure, small resistance, good shape, wear resistance and pressure resistance. It can be disassembled, assembled and cleaned to make it durable. Dumpling wrapper machine is designed scientifically and automatically. Combining with the characteristics of dumpling wrapper forming, dumpling wrapper machine adopts the principle of double-control and two-way synchronous material supply.

There is no need to make another dough in production. It only needs to put the dough into the designated entrance of the dough, and the dumpling wrapper can be produced automatically when the machine starts. The main components of the multi-functional dumpling leather machine are made of stainless steel materials for food specialty required by the safety and hygiene standards of the modern food industry. Main structure and technological process of dumpling leather machine.

The imitation manual dumpling wrapper machine is designed and manufactured on the principle of continuous roll pressing on two sides and one-time forming. It consists of motor, reducer device, transmission device, two sets of feeding rolls, combined sheet rolling rolls and a set of forming rolls. The supporting equipment of the machine is dough mixer and kneading machine. The reconciled dough is poured into the hopper above the main machine and automatically fed to the roughing roll to press the surface. Then it passes through the forming roll, compacts and thins again, and enters the forming roll.

The surface is formed once through the mould, with medium thickness and thin edges. By conveying the belt, the shaped dumpling wrapper is sent out. The deviation of the conveying pedestal indicates that the left and right tightness are not the same. The handwheels at both ends should be adjusted to make them even. The machine adopts chain, sprocket drive, transmission part is gearbox structure, durable, reducing the operator's labor intensity. Notices for Dumpling Leather Machine. Tighten the parts and install them flat and firm. Operators must wear button sleeve overalls, not to mention extending their hands into hoppers.Hard impurities must be removed from flour. Oil can't replace edible oil. Rotate clockwise to prevent reversal. Eating dumplings is a habit of Chinese people.

In the past, people mostly ate dumplings during the holidays. Now, with the improvement of production level, eating dumplings has become a household meal. If you want to eat, you can cook it. How to make a dumpling machine? Take 500 grams of flour, 200-225 grams of clear water and 2-5 grams of salt.

Add salt to the flour, mix evenly, pour clear water into the flour, while stirring the flour into flocculent. (Mixing dough machine works better). After shaping, knead for at least 3-5 minutes until the dough surface is smooth, cover and wake up for about 10 minutes. Knead the dough into strips, cut into equal parts, take one of them and rub it into flat strips for reserve, and put the rest back in the basin, cover it and set aside. This item is in the category "Home & Garden\Kitchen, Dining & Bar\Small Kitchen Appliances\Food Processors".

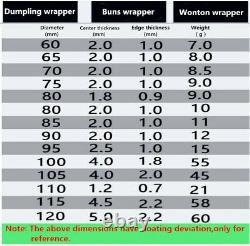

The seller is "zhenghuanliang" and is located in this country: CN.- wrapper's diameter & thickness: Φ90mm,Thickness:1mm

- Model: 65494498

- Country/Region of Manufacture: China

- Color: As shown

- Power: 250 W

- Brand: zhenghuanliang